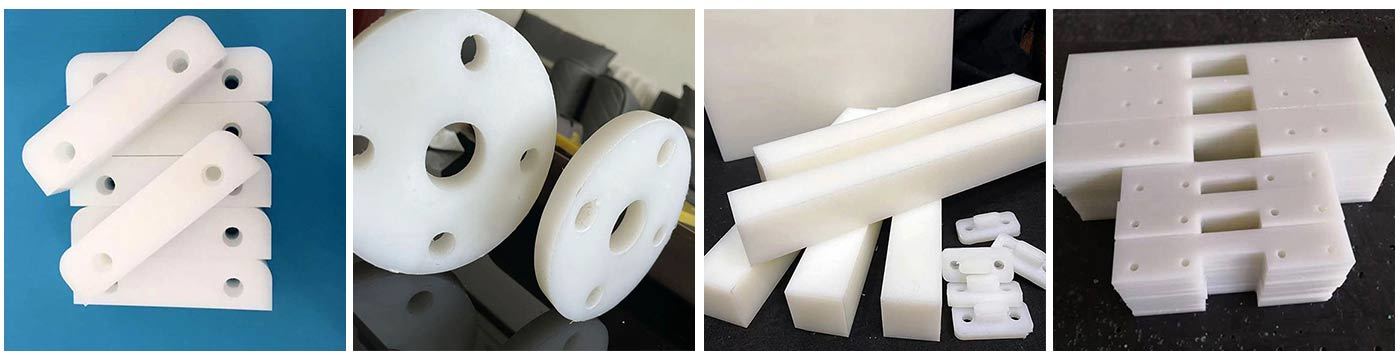

Customized plastic parts

Category:

Processed parts

Product Description

Customized plastic parts refer to plastic components or products that are specifically designed and manufactured according to custom specifications and requirements. These parts can be made from various types of plastics, such as polyethylene (PE), polypropylene (PP), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and more. Here is an overview of the process and applications of customized plastic parts:

Process of Customizing Plastic Parts:

-

Design: The customization process begins with designing the plastic part based on the customer's requirements. This involves creating a CAD (Computer-Aided Design) model that specifies the dimensions, shape, features, and any other specifications.

-

Material Selection: Choosing the appropriate plastic material is crucial based on factors such as strength, flexibility, temperature resistance, chemical resistance, and aesthetic requirements. Different plastics have varying properties, so selecting the right material is essential for the desired functionality and performance of the part.

-

Manufacturing Method: There are several methods for manufacturing customized plastic parts, including injection molding, blow molding, extrusion, thermoforming, and CNC machining. The manufacturing method is determined by factors like complexity, quantity, cost, and lead time.

-

Tooling and Prototyping: Custom plastic parts typically require tooling, which involves creating molds or dies used in the manufacturing process. Prototyping is often done to ensure that the design meets the customer's expectations before mass production.

-

Production: Once the design, material, and manufacturing method are finalized, the production of the customized plastic parts begins. The manufacturing process varies depending on the chosen method, with each method having its own specific steps and considerations.

Applications and benifits of Customized Plastic Parts:

-

Automotive Industry: Custom plastic parts are widely used in the automotive industry for interior and exterior components, such as dashboards, door panels, bumpers, grilles, and trim pieces.

-

Electronics and Appliances: Plastic parts are integral to electronics and appliances, including casings, housings, buttons, connectors, and display panels.

-

Medical Devices: Custom plastic parts are used in the manufacturing of medical devices and equipment, ranging from syringes and IV components to prosthetics and surgical instruments.

-

Consumer Goods: Various consumer products utilize customized plastic parts, such as toys, packaging containers, bottles, kitchenware, and household appliances.

-

Industrial Equipment: Plastic parts find applications in industrial machinery and equipment, including gears, pulleys, conveyor components, and protective covers.

-

Aerospace and Defense: The aerospace and defense industries employ customized plastic parts for aircraft interiors, cockpit components, missile casings, and other specialized applications.

-

Building and Construction: Plastic parts are utilized in building and construction projects for window profiles, piping systems, insulation materials, roofing components, and architectural features.

-

Sports and Recreation: Items like sporting equipment, outdoor gear, and recreational products often incorporate customized plastic parts for enhanced performance and durability.

Customized plastic parts offer flexibility in design and functionality, allowing for precise tailoring to specific requirements. They are essential in numerous industries and applications, contributing to the advancement and innovation of various products and systems.

Company Profile

Packing and shipping

Costomized processing video:

FAQ

Q

6.Why chose us?

A:

Q

5.Where are we?

A:

Q

4.What we do?

A:

Q

3.What is UHMWPE Sheet used for?

A:

Q

3.What is UHMWPE Sheet used for?

A:

Q

2.Why should you choose UHMWPE Sheet?

A:

Related Products

Online Message